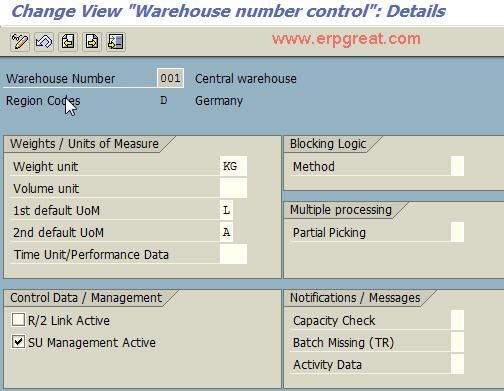

IMG Path:

SPRO -> Logistics Execution -> Warehouse Management -> Master Data -> Define Control Parameters for Warehouse Number

Transaction Code: SPRO / SM30 (Table / View T340D / V_T340D)

Field description:

- Region Code

Region code is assigned to the warehouse for Hazardous Materials Management Functions. This code is assigned in the configuration for Hazardous Materials Management.

- Weights/Units of Measure

- Time Unit / Performance Data

The unit of measure defined here in this field is used by the system for all time calculations for performance in the warehouse. For example, the planned TO Processing time is recorded in the TO in this Time Unit.

- Other details

Method for Blocking Logic is defined as one of the control parameters here. This blocking logic will control the simultaneous operations in the warehouse.

- Storage Unit Management is activated at Warehouse Level in the control parameters only.

- Capacity Check Method

If the capacity check is switched on in a storage type, you can use this indicator to control whether a warning message, an error message, or no message at all is to be issued by the system whenever there is not enough weight available in the material master (capacity check for weight) or insufficient quantity (capacity check for quantity).

- Weight/Volume Unit

The weights/volume of all the materials managed in the warehouse is managed in the unit of weight/volume that is specified in Weight/volume Unit field while defining warehouse. All weights are managed in the warehouse in the unit of weight that is specified in the Weight Unit field in this section . In the case of movements, the material weight is converted to this unit of weight and updated in the storage bins. The capacity check by weight is also made in this unit. Here, the maximum accuracy is 1/1000 of this unit of weight.

- Note

It is not advisable to change this unit of weight in a productive environment. In case it is unavoidable, data must be corrected by running report RLS10200 afterwards.

- Default UoM

The system selects this unit of measure first for use in the warehouse if no default unit of measure was defined in the material master

-- Use

If no UoM is available in the material master, the system tries to assign one of the defaults from the warehouse number record. If these defaults have not been maintained, the system uses the base Unit of Measure

-- 1st Proposal UoM

The Unit of Measure defined in this field is taken as a default for a transaction of a material if system do not find any unit of measure from the material master record for that material.

-- 2nd Proposal UoM

The Unit of Measure defined in this field is taken as a default for a transaction of a material if system do not find any unit of measure from the material master record for that material.

- Time unit/Performance Data

The time unit maintained here is used while processing performance data. The Planned TO time and the Time Limits of Critical Objects in Warehouse Activity Monitor is maintained in this Unit.

- Blocking Method

The setting maintained in this field controls the degree to which multiple users are allowed to remove materials from the storage bins of the warehouse.

- Partial Picking

This field controls the type of partial picking allowed in this warehouse. It controls the partial picking for material for TR and Delivery processing.

- Capacity Check

This indicator controls the issue of messages in the case of incorrect data for capacity check function. If the capacity check function is activated in a Storage Type, we can control by using this indicator whether a warning message or an error message is issued in the case of missing weight in the Material Master Record.

- Batch Missing during TR Creation

This setting controls whether a warning or an error message or no message at all, need to be displayed if batch is missing for a material which is handled in batches, at the time of TR Creation for this material.

- SU Management

If the warehouse is using Storage Units Management Function, then this indicator need to be activated. At the same time this indicator will also be activated for storage types in this warehouse.

- Performance Data

To control whether an error or warning or no message to be displayed if some parameter is missing while processing planned TO data.