Will the maintenance plans actually stay deleted or are they just flagged as deleted. We also just want to make sure that we don't double schedule.

Answer

Why are you deleting your existing maintenance plans? Are you going to use existing Maintenance Items and Task List?

Assuming same MItems/Task List are used, if I were you I would do these:

1. List all existing MPlans (IP16), then check all the Work Orders generated by the existing MPlans.

- If the work order has been Approved/Released, most likely the work is already being prepared for execution OR already in the schedule depending on the Schedule start date. It could also be that materials and services have already been "ordered" using this work order - therefore, I would not delete these. Check with the owner of the WO or the last person who changed it.

- If the work order has INIT status and scheduled start date is not in the near future, maybe these WO can be deleted and let the new maintenance plan generate the new work orders. But then again download a report and let the process owner decide if the work can be deleted.

2. I would put a prefix "DEL" in the description of the deleted Maintenance Plans so you can easily identify that the maintenance plan has deleted status flag.

3. How about the Maintenance Items? are you using the same Maintenance Items in you new MPlans?

- If yes, no worries.

- If not - don't forget to delete. Also check the object list of your new maintenance items and ensure all object list from old MItems are include (or excluded).

Deleting Maintenance Plan - The MPlan is still in the system, only the Deletion Flag is set (Flagged as deleted). All scheduled Calls will be Locked (will no longer generate Work Orders)

Double Schedule - what do you mean by this? If you delete the existing work orders (INIT status with future scheduled start date) and let the new MPlan generate new work order then you avoid WO double-ups. NOTE: You might want to take into consideration the completion date of the last work order in scheduling your new Maintenance Plan.

Notes:

Instead of deleting & creating a new plan suggestion if it can meet your requirement is as given below:

1. Create new maintenance item, you wish to assign to the plans.

2. Delete present maintenance item (one min item requires in each plan mandatory requirement) & assign new maintenance item to the same plan.

3. Change scheduling parameter & planning parameter for your plans.

Further notes:

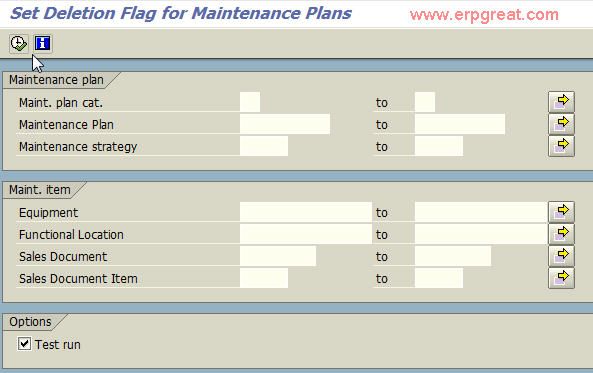

You can use IP25 to set deletion flag (test run it first) in mass but to set it inactive, you have to do manually or use tcode LSMW.

Inactive: Making Maintenance Plans inactive temporarily. Again you can make that active for further scheduling.

Deletion Flag: If you want to delete that Maintenance Plan permanently, you can set deletion flag & you can archive those maintenance plans.

ABAP people can write a BDC program to deactivate the maintenance plans in mass. I think, there is no standard program or BAPI to do that.